Joint Chiefs Vice Chairman Visits Marshall

Navy Adm. Christopher Grady, vice chairman of the Joint Chiefs of Staff, his wife Christine Grady, and son Luke Grady talk with Nick Benjamin, right, a payload operations director for the International Space Station, at the Payload Operations Integration Center during the vice chairman's tour of NASA's Marshall Space Flight Center on May 6. (NASA/Charles Beason)

Marshall Team Members Honored with Space Flight Awareness Awards

Astronaut Victor Glover, far right, and Bill Hill, second from right, director of safety and mission assurance at NASA's Marshall Space Flight Center join Marshall honorees for a photo op at the Space Flight Awareness Honoree Ceremony on May 4 in Orlando, Florida. Honoree awards recognize civil servants and industry partners for outstanding work and dedication to astronaut safety. From left, Cody Goodman, David Starrett, John Ivester, Lisa Hughes, Greg Snell, Megan Vansant, Megan Hines, Karl Nelson, Les Johnson, Shawn Reagan, Hill, and Glover. Marshall honorees also include Maggie Freeman, who was unable to attend the awards event. (NASA)

NASA's Boeing Crew Flight Test Eyes Next Launch Opportunity

NASA, Boeing, and ULA (United Launch Alliance) teams continue working remaining open tasks in preparation for the agency's Boeing Crew Flight Test to the International Space Station. The teams now are targeting a launch date of no earlier than 3:43 p.m. CDT May 21, to complete additional testing.

On May 11, the ULA team successfully replaced a pressure regulation valve on the liquid oxygen tank on the Atlas V rocket's Centaur upper stage. The team also performed re-pressurization and system purges, and tested the new valve, which performed normally.

The Atlas V and Starliner remain in the Vertical Integration Facility at Space Launch Complex-41 on Cape Canaveral Space Force Station.

NASA astronauts Butch Wilmore and Suni Williams, still in preflight quarantine, returned to Houston on May 10 to spend extra time with their families as prelaunch operations progress. The duo will fly back to NASA's Kennedy Space Center in the coming days.

Wilmore and Williams are the first to launch aboard Boeing's Starliner to the space station as part of the agency's Commercial Crew Program. The astronauts will spend about a week at the orbiting laboratory before returning to Earth and making a parachute and airbag-assisted landing in the southwestern United States.

After successful completion of the mission, NASA will begin the final process of certifying Starliner and its systems for crewed rotation missions to the space station.

I Am Artemis: Lauren Fisher

Not many music majors get to be hands-on with building a Moon rocket, but Lauren Fisher has always enjoyed the unusual.

Now a structural materials engineer at NASA's Marshall Space Flight Center, Fisher works on a key adapter for NASA's SLS (Space Launch System) rocket for the first crewed missions of NASA's Artemis campaign.

Manufactured at Marshall by NASA, lead contractor Teledyne Brown Engineering, and the Jacobs Space Exploration Group's ESSCA contract, the cone-shaped launch vehicle stage adapter partially encloses the rocket's interim cryogenic propulsion stage and connects it to the core stage below and the Orion stage adapter above. The launch vehicle stage adapter also protects avionics and electrical devices from extreme vibration and acoustic conditions during launch and ascent.

Fisher and the thermal protection system team develop and apply the spray-on foam that acts as insulation and protects the adapter and all its systems from the extreme pressures and temperatures it'll face during flight. The thermal protection system for the component, unlike other parts of the rocket, is applied by hand using a spray gun. When first applied, the insulation is yellow, but after time and exposure to the Sun, it turns orange.

"We're taking the same stuff someone might use to insulate their attic, except making it for cryogenic atmospheres, and spraying it all over a giant piece of hardware that will help launch us to the Moon," Fisher said. "With my work for NASA's Space Launch System rocket, I get to play with foam and glue. I like to call it arts and crafts engineering!"

Although engineering runs in her family, Fisher initially graduated from University of Southern Mississippi with a Bachelor of Arts in music performance and an interest in music education. She developed an interest in carbon-based polymers, and decided to go back to school, completing a chemical engineering degree with a polymeric materials track from the University of Alabama in Huntsville. Her new degree led to an opportunity to work for the thermal protection system team at Marshall.

When Fisher isn't in the office, she likes travelling to unusual places and checking items off her self-described "Bizarre Bucket List." Recently, she went to Punxsutawney, Pennsylvania, to watch the famous groundhog predict an early spring.

Being part of the Artemis Generation is incredibly inspiring for Fisher, who takes pride in her work supporting the first three Artemis missions, including Artemis II, the first crewed mission under Artemis, in 2025.

"I'm literally building the hardware that will send the first woman to deep space," Fisher says. "Watching our rocket take shape, I'm like 'you see that thing? I did that; that's mine. See that one? My team did that one. We did that, and see this?'" She beams with pride. "You can do that, too. Just being a part of the generation that's changing the workforce and changing the space program - it gives me goosebumps."

NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under Artemis. SLS is part of NASA's backbone for deep space exploration, along with the Orion spacecraft and Gateway in orbit around the Moon and commercial human landing systems, next-generational spacesuits, and rovers on the lunar surface. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.

NASA Licenses 3D-Printable Superalloy to Benefit US Economy

NASA's investment in a breakthrough superalloy developed for the extreme temperatures and harsh conditions of air and spaceflight is on the threshold of paying commercial dividends.

The agency is licensing its invention, dubbed "GRX-810," to four American companies, a practice that benefits the United States economy as a return on investment of taxpayer dollars.

GRX-810 is a 3D-printable high-temperature material that will lead to stronger, more durable airplane and spacecraft parts that can withstand more punishment before reaching their breaking point.

The co-exclusive license agreements will allow the companies to produce and market GRX-810 to airplane and rocket equipment manufacturers as well as the entire supply chain.

The four co-exclusive licensees are:

- Carpenter Technology Corporation of Reading, Pennsylvania

- Elementum 3D, Inc. of Erie, Colorado

- Linde Advanced Material Technologies, Inc. of Indianapolis

- Powder Alloy Corporation of Loveland, Ohio

GRX-810 is one example of many new technologies NASA's Technology Transfer Program managers review and file for patent protection. The team also works with inventors to find partners interested in commercialization.

"NASA invests tax dollars into research that demonstrates direct benefit to the U.S. and transfers its technologies to industry by licensing its patents," said Amy Hiltabidel, licensing manager at NASA's Glenn Research Center.

NASA engineers designed GRX-810 for aerospace applications, including liquid rocket engine injectors, combustors, turbines, and hot-section components capable of enduring temperatures over 2,000 degrees Fahrenheit.

"GRX-810 represents a new alloy design space and manufacturing technique that was impossible a few years ago," said Tim Smith, materials researcher at NASA Glenn.

Smith co-invented the superalloy along with his Glenn colleague Christopher Kantzos using a time-saving computer modeling and laser 3D-printing process that fuses metals together, layer-by-layer. Tiny particles containing oxygen atoms spread throughout the alloy enhance its strength.

Compared to other nickel-base alloys, GRX-810 can endure higher temperatures and stress and can last up to 2,500 times longer. It's also nearly four times better at flexing before breaking and twice as resistant to oxidation damage.

"Adoption of this alloy will lead to more sustainable aviation and space exploration," said Dale Hopkins, deputy project manager of NASA's Transformational Tools and Technologies project. "This is because jet engine and rocket components made from GRX-810 will lower operating costs by lasting longer and improving overall fuel efficiency."

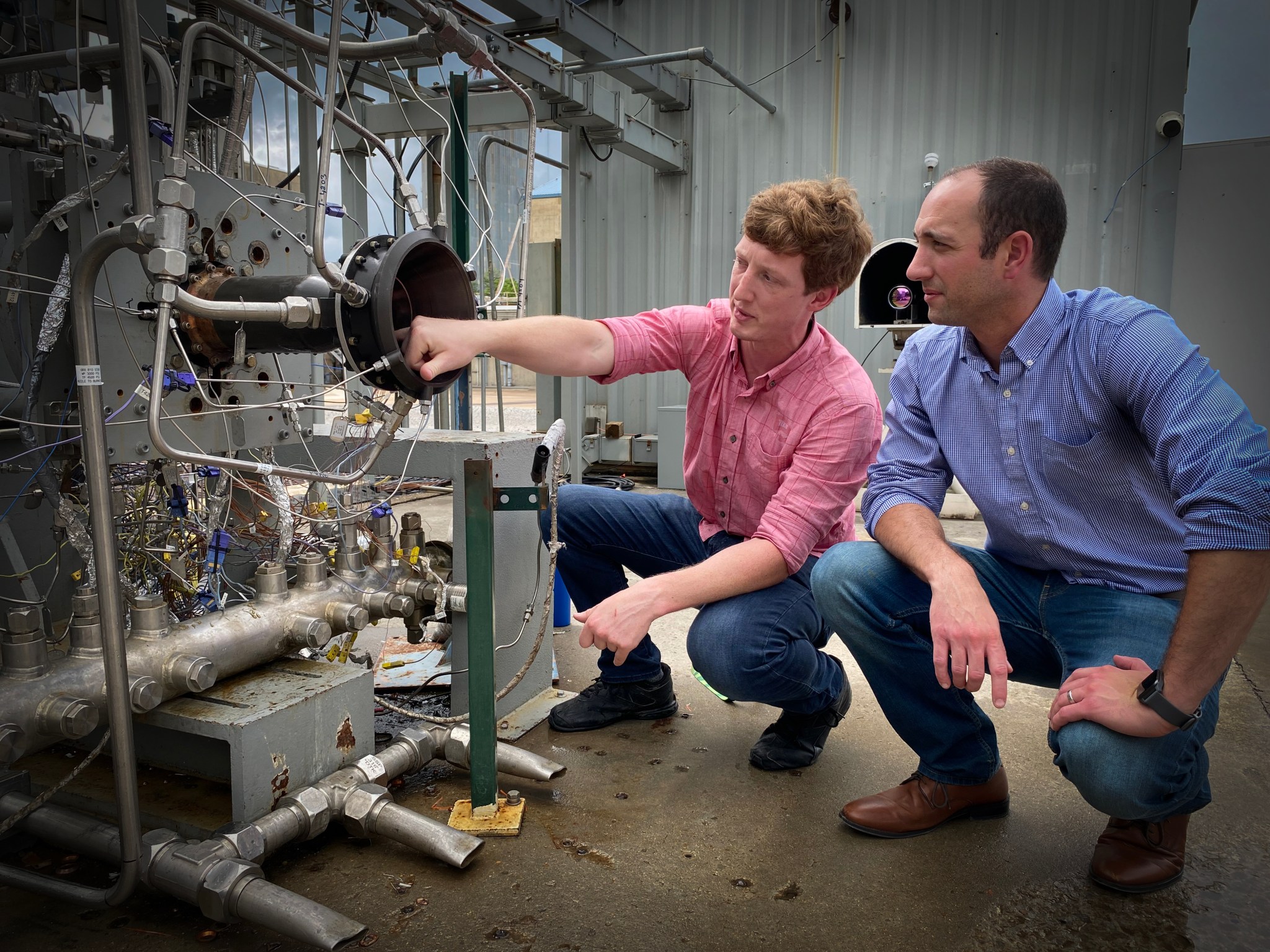

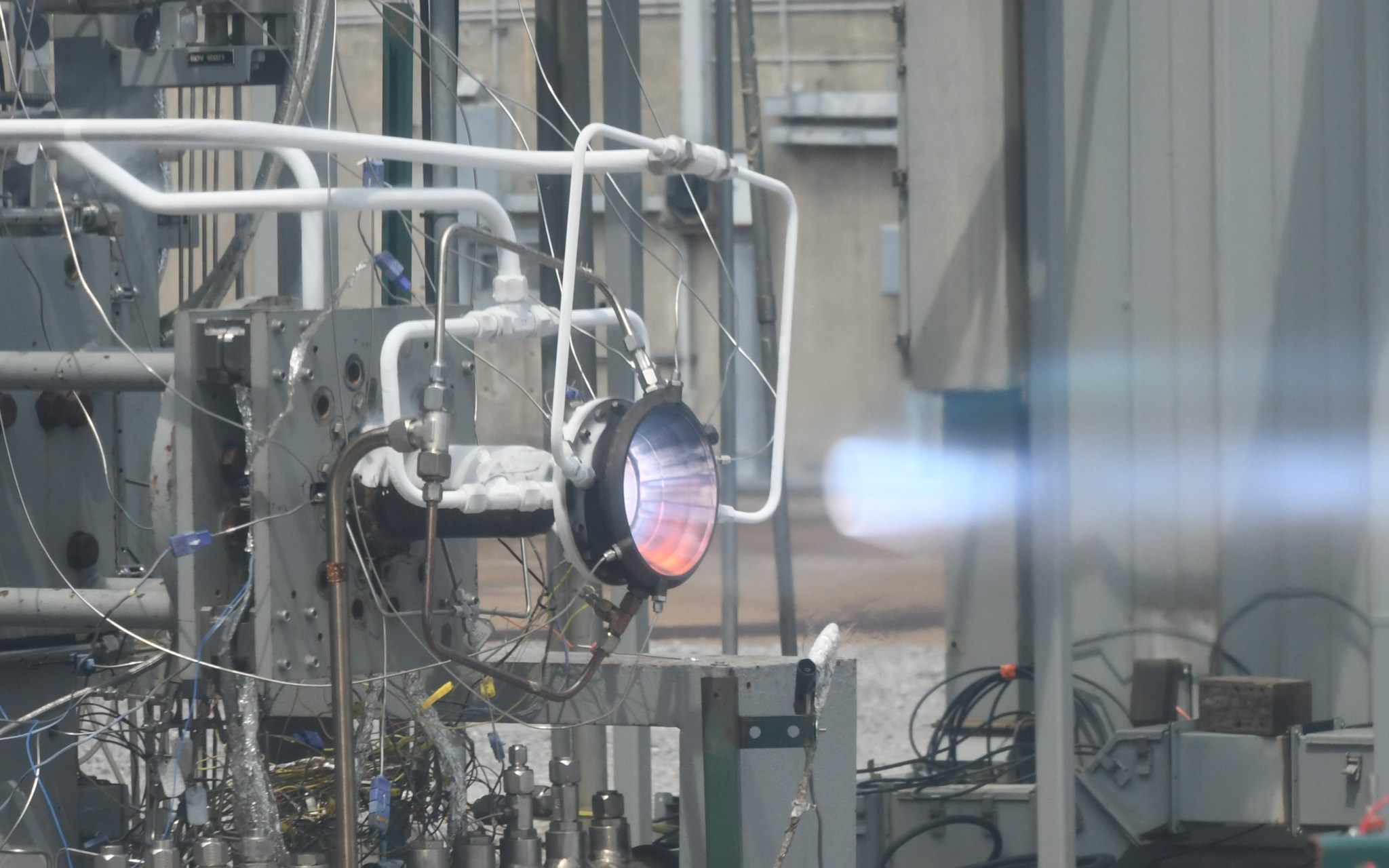

Research and development teams include those from Glenn, NASA's Ames Research Center, Ohio State University, and NASA's Marshall Space Flight Center, where the most recent testing included 3D-printed rocket engine parts.

Marshall completed a successful hot-fire test series at Test Stand 115 in 2023. This test series demonstrated GRX-810 injectors and regeneratively cooled nozzles for liquid rocket engines. The center is working to advance additive manufacturing for propulsion applications, but also developing 3D-printing technologies to deploy in space for manufacturing. Marshall has capabilities for the entire design, analysis, manufacturing, hot- fire testing, and certification lifecycle of complex additively manufactured propulsion components and engine systems to enable high performance for NASA, government, and commercial space missions.

NASA develops many technologies to solve the challenges of space exploration, advance the understanding of our home planet, and improve air transportation. Through patent licensing and other mechanisms, NASA has spun off more than 2,000 technologies for companies to develop into products and solutions supporting the American economy.

Agency's New Mobile Launcher Stacks Up for Future Artemis Missions

The foundation is set at NASA's Kennedy Space Center for launching crewed missions aboard the agency's larger and more powerful SLS (Space Launch System) Block 1B rocket in support of Artemis IV and future missions. On May 9, teams with NASA's EGS (Exploration Ground Systems) Program and contractor Bechtel National Inc. transferred the primary base structure of the mobile launcher 2 to its permanent mount mechanisms using the spaceport's beast-mode transporter - the crawler.

The mobile launcher serves as the primary interface between the ground launch systems, SLS rocket, and Orion spacecraft that will launch the SLS Block 1B rocket, with its enhanced upper stage, to the Moon, allowing the agency to send astronauts and heavier cargo into lunar orbit than its predecessor, SLS Block 1. With Artemis, NASA will land the first woman, first person of color, and its first international partner astronaut on the lunar surface and establish long-term exploration for scientific discovery and to prepare for human missions to Mars.

NASA's Marshall Space Flight Center manages the SLS Program.

Read more about the mobile launcher.

Chandra Notices the Galactic Center is Venting

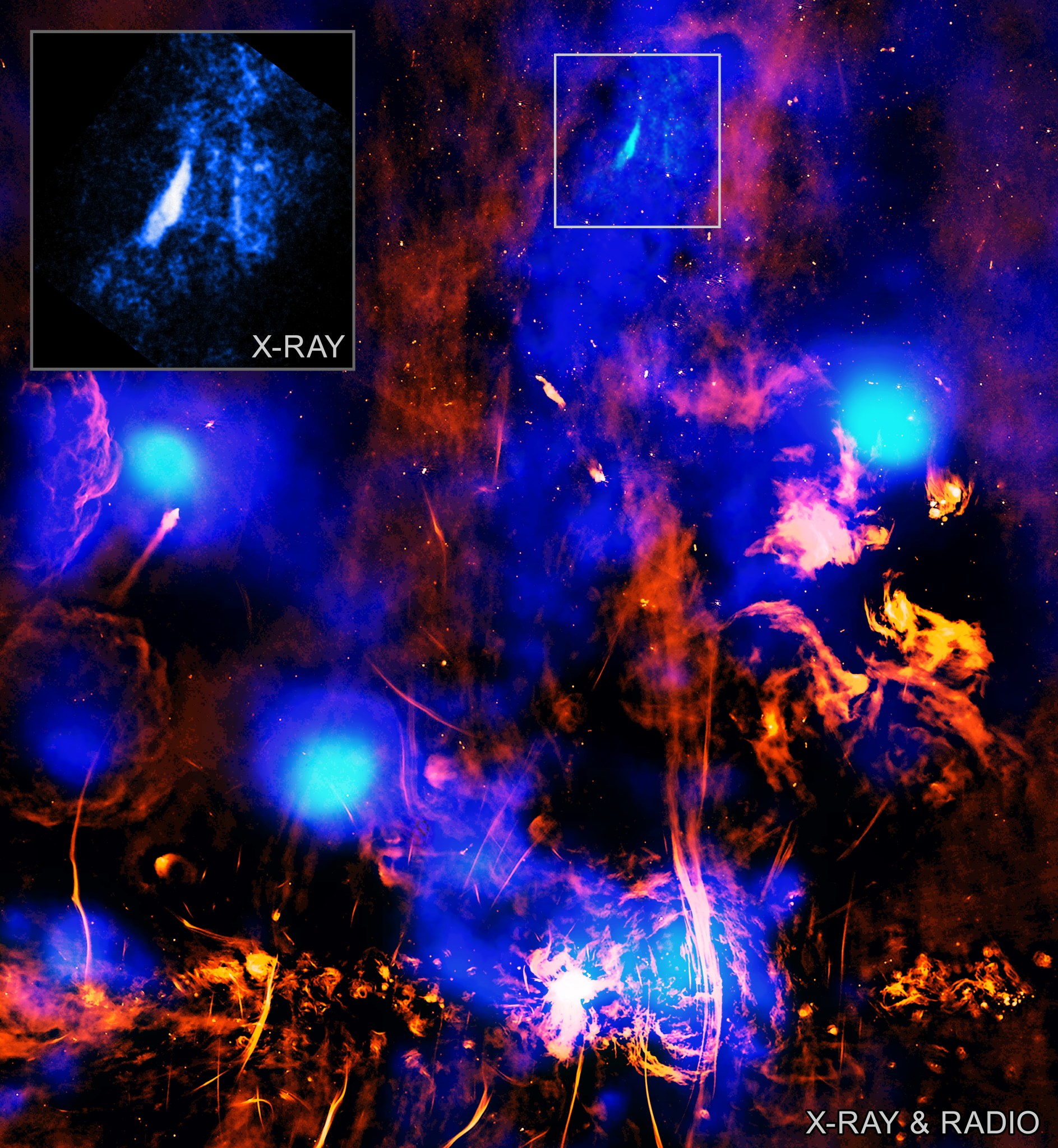

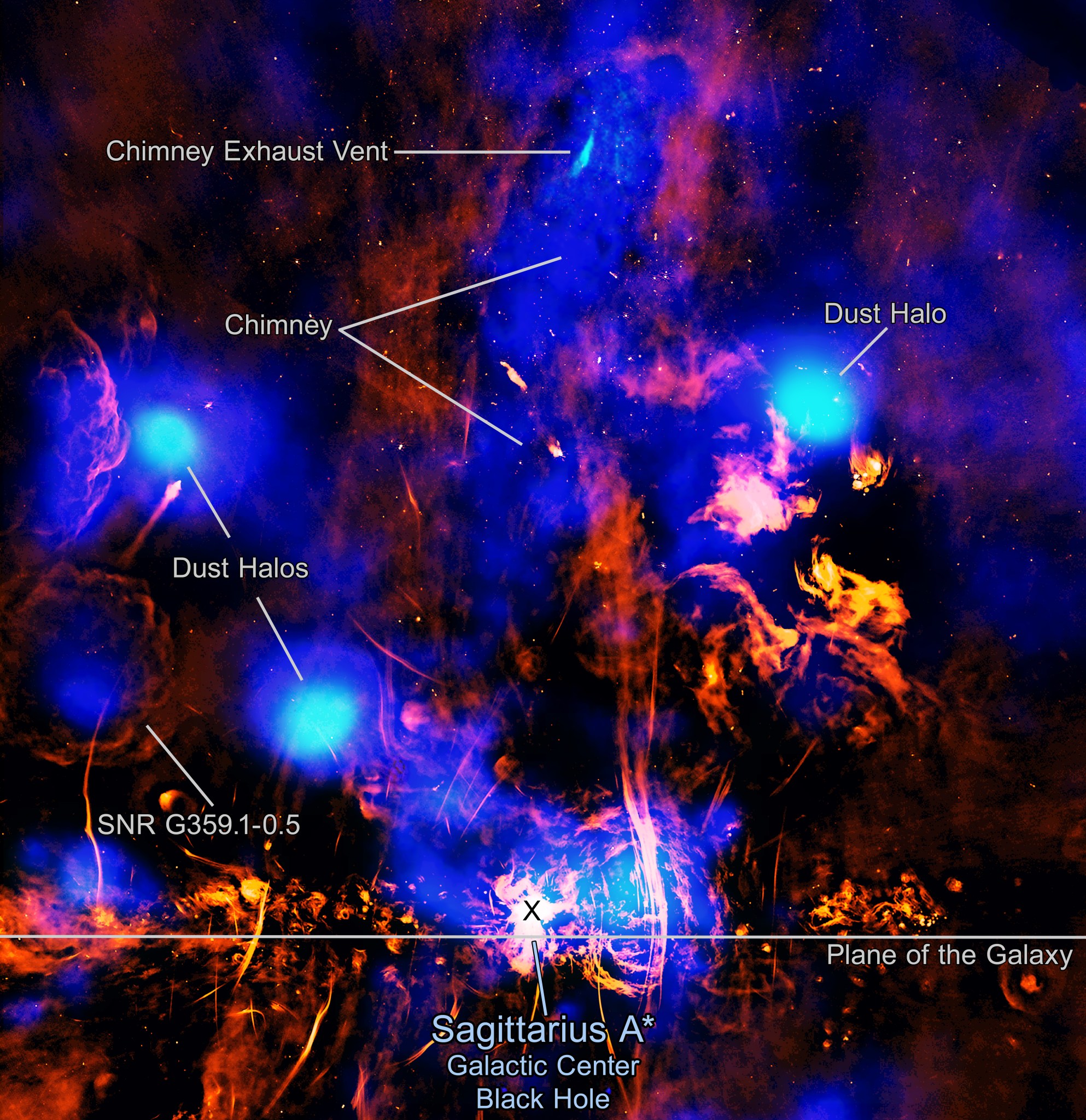

Recent images show evidence for an exhaust vent attached to a chimney releasing hot gas from a region around the supermassive black hole at the center of the Milky Way, as reported in a press release. In the main image of this graphic, X-rays from NASA's Chandra X-ray Observatory (blue) have been combined with radio data from the MeerKAT telescope (red).

Previously, astronomers had identified a "chimney" of hot gas near the Galactic Center using X-ray data from Chandra and ESA's XMM-Newton. Radio emission detected by MeerKAT shows the effect of magnetic fields enclosing the gas in the chimney.

The evidence for the exhaust vent is highlighted in the inset, which includes only Chandra data. Several X-ray ridges showing brighter X-rays appear in white, roughly perpendicular to the plane of the Galaxy. Researchers think these are the walls of a tunnel, shaped like a cylinder, which helps funnel hot gas as it moves upwards along the chimney and away from the Galactic Center.

A labeled version of the image gives the locations of the exhaust vent, the chimney, the supermassive black hole at the center of the Milky Way Galaxy (called Sagittarius A*, or Sgr A* for short) and the plane of the galaxy.

This newly discovered vent is located near the top of the chimney about 700 light-years from the center of the Galaxy. To emphasize the chimney and exhaust vent features the image has been rotated by 180 degrees from the conventional orientation used by astronomers, so that the chimney is pointed upwards.

The authors of the new study think that the exhaust vent formed when hot gas rising through the chimney struck cooler gas lying in its path. The brightness of the exhaust vent walls in X-rays is caused by shock waves - like sonic booms from supersonic planes - generated by this collision. The left side of the exhaust vent is likely particularly bright in X-rays because the gas flowing upwards is striking the tunnel wall at a more direct angle and with more force than other regions.

The researchers determined that the hot gas is most likely coming from a sequence of events involving material falling towards Sgr A*. They think eruptions from the black hole then drove the gas upwards along the chimneys, and out through the exhaust vent.

It is unclear how often material is falling onto Sgr A*. Previous studies have indicated that dramatic X-ray flares take place every few hundred years at or near the location of the central black hole, so those could play important roles in driving the hot gas upwards through the exhaust vent. Astronomers also estimate that the Galactic black hole rips apart and swallows a star every 20,000 years or so. Such events would lead to powerful, explosive releases of energy, much of which would be destined to rise through the chimney vent.

The paper describing these results is published in The Astrophysical Journal and a preprint is available online. The authors of the paper are Scott Mackey (University of Chicago), Mark Morris (University of California, Los Angeles), Gabriele Ponti (Italian National Institute of Astrophysics in Merate), Konstantina Anastasopoulou (Italian National Institute of Astrophysics in Palermo), and Samaresh Mondal (Italian National Institute of Astrophysics in Merate).

NASA's Marshall Space Flight Center manages the Chandra program. The Smithsonian Astrophysical Observatory's Chandra X-ray Center controls science operations from Cambridge, Massachusetts, and flight operations from Burlington, Massachusetts.